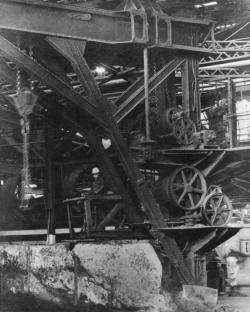

Used to lift molten iron to molds where it was cast into pipe, jib cranes were the sole means of conveyance in the pit-casting process. When pit casting was replaced by centrifugal casting in the 1920s, many pits were filled and the cranes were used to produce cast iron fittings or general maintenance work. Only one jib crane remained at the American Cast Iron Pipe Company in recent years, and it was probably the last pit-cast jib crane to operate, which it did until it was given to the Sloss Furnace Museum in early 1986.

Furnace

Wisconsin Historical Society Image Caption: East Wells Onieda Street Power Plant Era_date_from: 1918

Montogomery Bell was a land developer and iron maker who purchased the Harpeth Narrows site to expand his industrial empire - which ultimately consisted of 14 iron blast furnaces throughout middle Tennessee.

The Harpeth River makes a tight bend around a steep limestone ridge, losing 17 feet of elevation in a run of 5 1/2 miles. Bell excavated a tunnel through the limestone ridge, creating a shortcut for the river. The hydropower derived from this drop in elevation was used to drive the Patterson Iron Works built by Bell.

Montogomery Bell was a land developer and iron maker who purchased the Harpeth Narrows site to expand his industrial empire - which ultimately consisted of 14 iron blast furnaces throughout middle Tennessee.

The Harpeth River makes a tight bend around a steep limestone ridge, losing 17…

Read More

Used to lift molten iron to molds where it was cast into pipe, jib cranes were the sole means of conveyance in the pit-casting process. When pit casting was replaced by centrifugal casting in the 1920s, many pits were filled and the cranes were used to produce cast iron fittings or general…

Read More